DASAG powder pump

Based on the basic principle of a double diaphragm pump, we developed a special “powder pump” for conveying a wide range of powders and granulates.

For over 30 years now, the DASAG powder pump has been used successfully in over 500 applications with more than 200 different bulk materials.

Due to its properties, it offers technical and economic advantages compared to conventional pneumatic conveying systems. Since its market launch, it has demonstrated these advantages to well-known companies in the bulk materials processing industry.

Typical projects with the DASAG powder pump include the conveying and dosing of bulk materials that are difficult to handle, sometimes even under critical operating conditions (e.g. explosive atmospheres).

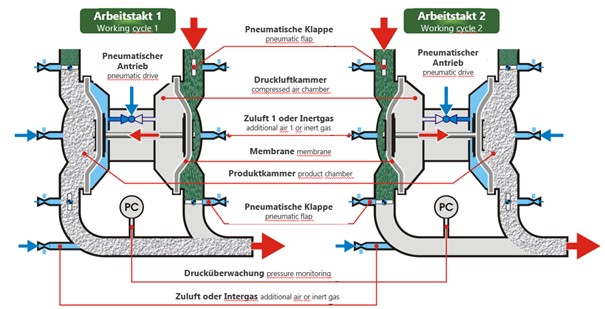

Working principle

Properties

Technical and economical advantages

- fully pneumatic operation

- suitable for almost all powders (even “heavy” ones)

- wide range of applications as a conveying unit and dosing unit

- product-friendly conveying process

- conveying takes place at low speeds and low pressures

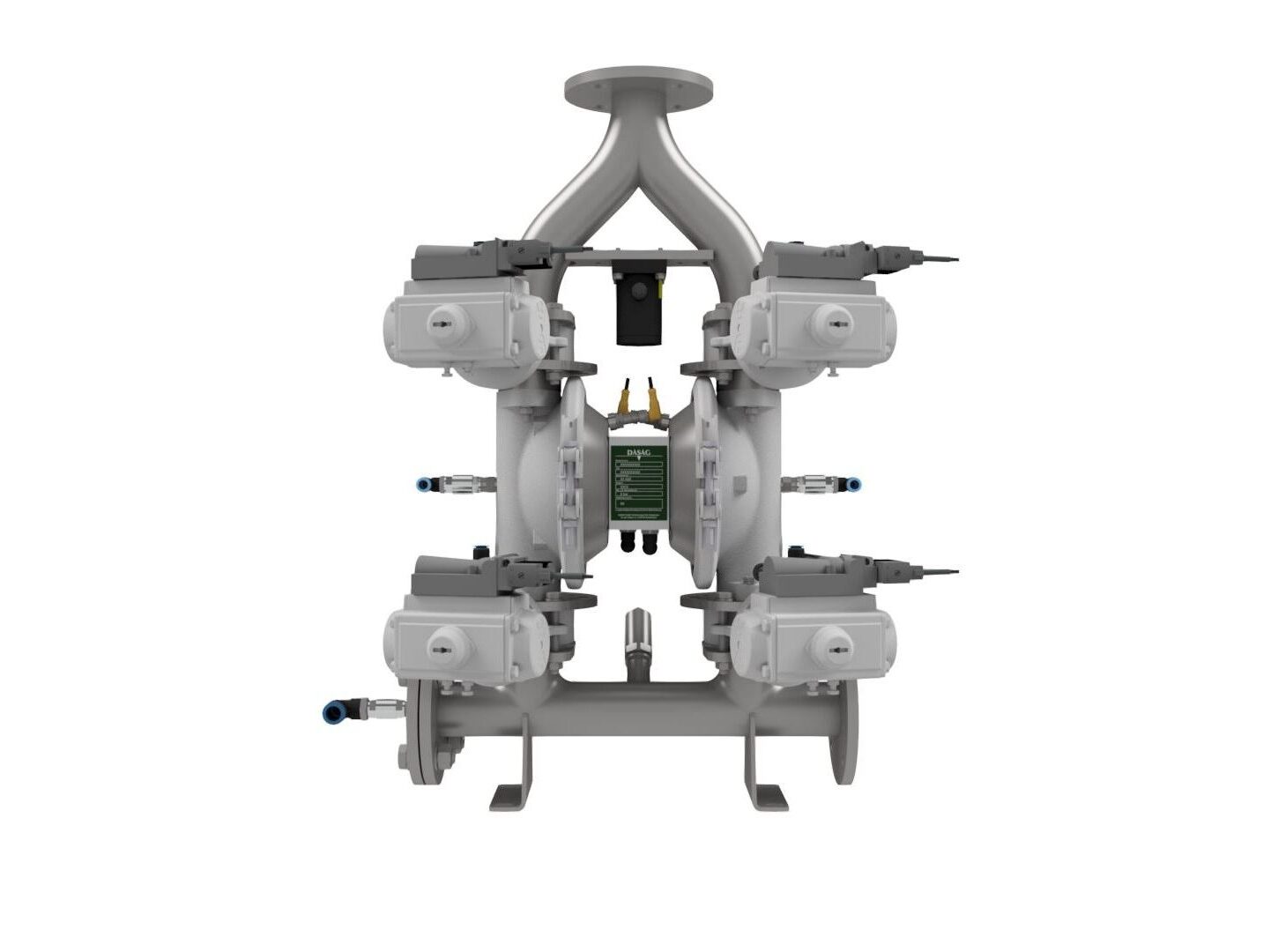

- compact design and control via PLC enables flexible use

- conveying capacity up to approx. 10 m³/h

- conveying distances of up to 40 m and more

- small expansion chambers and small dedusting areas at the target stations

- function of a discharge aid due to the possibility of “back-fluidisation”

- intrinsic safety of the system due to permanent conveying pressure monitoring

- Obligation to test the entire system in accordance with the Pressure Equipment Directive may not apply under certain circumstances

- Type examination for use in hazardous areas

Possible applications

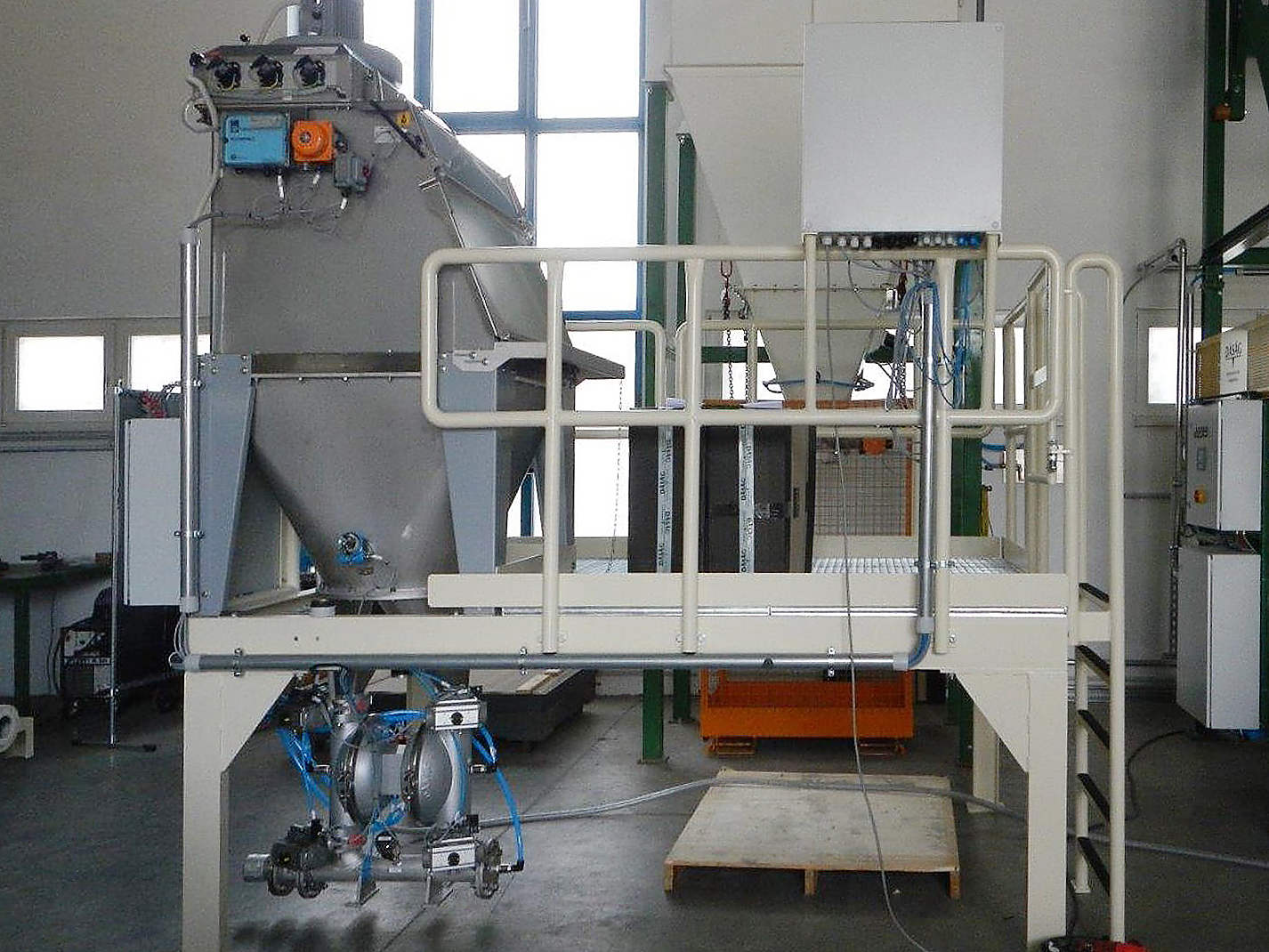

Powder pumps are often part of complete systems for handling bulk materials in dosing, mixing, packaging or recycling systems.

Container emptying

Silo emptying

BIG BAG emptying

Sack emptying

DASAG powder pump SD40 as dosing pump